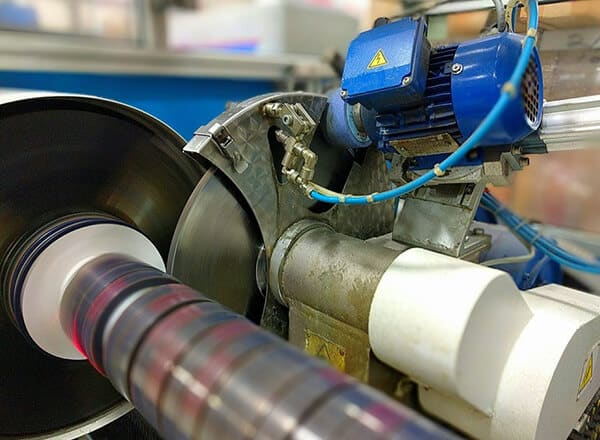

Lathe Slitting

Ameritape specializes in custom adhesive tape precision slitting. We have multiple lathe slitters that cut a wide variety of materials. Lathe slitting involves spinning log rolls on a mandrel while a computer-guided blade makes precision cuts to preprogrammed widths. Logs of material for lathe slitting can be as wide as 60” and can be cut as narrow as .06” with a tolerance of +/- .03”